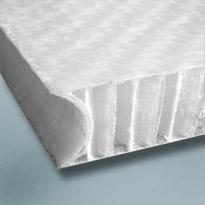

MonoPan® – simply in great shape

MonoPan® is a thermoplastic composite material and thus perfectly suitable for thermal forming.

Easy hot and cold formability of MonoPan® offers large scale weight reductions and enormous economies of scale for finished products.

Bending

Even large sized panels could be formed by bending. Depending on the specific requirements it is possible to achieve structures bent by heated tools in two or three dimensions. The resulting self-supporting structures are used for tanks, special packaging or in the automotive industry. By the lack of connecting profiles or additional framework considerable weight savings are possible.

The originally plain and simple panel is transformed into a self-supporting structural part.

Weight, the number of parts, assembly time and thus costs are reduced substantially.

Bending (Thermal and mechanical)

Edge Shaping and Closing

Additionally, MonoPan® offers the possibility for closed contours and edges in order to protect the polypropylene honeycomb core from corrosion. Alternatively to attaching additional cover profiles, e.g. made of aluminium or composites, the edges could be closed in different ways: either by thermally welded edge closings (thermoforming the panel edges themselves or by welding a thermoplastic strip onto the edges) or by glued edge closings.